Where to Use Strip and Midi Fuses?

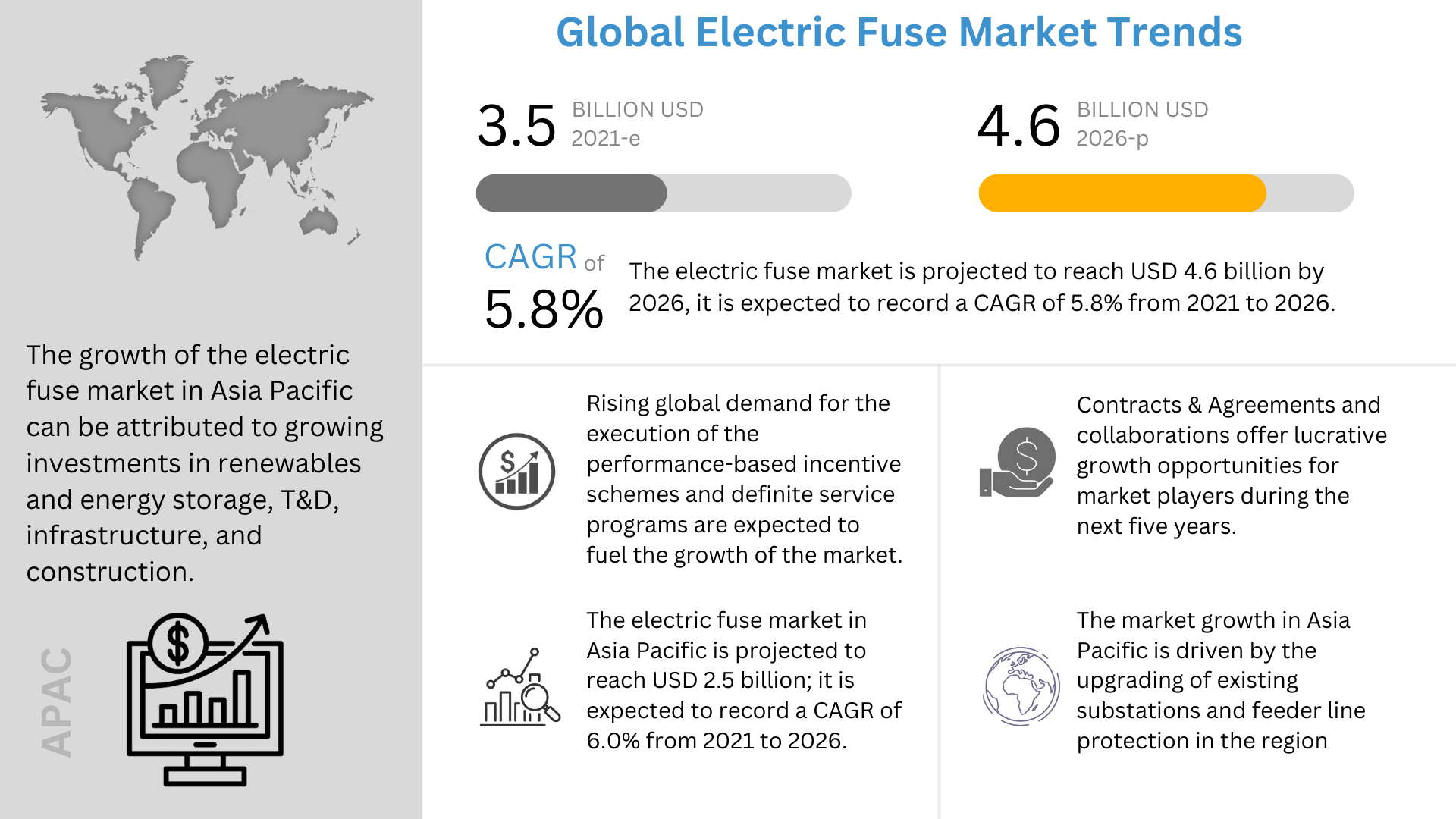

The demand for global electric fuse is swelled to reach a size of USD 4.6 billion by 2026; at a CAGR of 5.8, from an estimated USD 3.5 billion in 2021. adding leaguers in construction assiduity laying to rapid-fire urbanization; and high demand for electric fuses in the construction region are the crucial procurators driving the excrescency of the electric fuse demand. If you are looking to protect your circuits with ease - place your order for Midi Fuses Online in UK from UK Cable ties today!

Source: Markets and Markets

Strip Fuses:

Strip fuses, also known as blade fuses or automotive fuses, are electrical safety devices used to protect electrical circuits from excessive current flow. They are commonly used in automobiles, trucks, and other vehicles, as well as in various electrical systems and equipment.

Strip fuses consist of a plastic housing with two metal blades or strips fused inside. The housing is usually transparent, allowing visual inspection of the fuse element. The metal strips are made of a conductive material that is designed to melt or break when the current flowing through the fuse exceeds its rated value. This interruption of current flow helps prevent damage to the electrical system or equipment and reduces the risk of fire or other safety hazards.

Strip fuses are available in different current ratings, ranging from a few amperes to several hundred amperes. The most common types of strip fuses include standard ATO (Automotive Type) fuses, mini fuses, and micro fuses. The physical dimensions and blade configurations may vary depending on the specific fuse type and its amperage rating.

When a fault or excessive current occurs in the circuit protected by a strip fuse, the fuse will blow or "trip," breaking the circuit and cutting off the flow of electricity. This requires the fuse to be replaced with a new one of the same rating. It is important to use the correct current rating for replacement fuses to ensure proper protection and prevent potential damage to the electrical system.

Strip fuses are typically located in fuse boxes or panels, which are often found in the engine compartment, under the dashboard, or in other accessible areas of vehicles or equipment. They are marked with their current rating and may also have color-coded housings or labels for easy identification.

UK Cable Ties ranks among the top cable ties and fuse suppliers in the UK that can fulfill all your electrical product needs. Fuse your worries away by shopping for Strip Fuses Online in UK!

Applications of Strip Fuses:

● Automotive: Strip fuses are extensively used in automobiles, trucks, motorcycles, and other vehicles. They protect electrical circuits in the vehicle, such as those powering headlights, taillights, turn signals, radios, power windows, air conditioning systems, and other components.

● Electrical Equipment: Strip fuses are employed in a wide range of electrical equipment and machinery to protect circuits from overcurrent conditions. This includes generators, inverters, battery chargers, power distribution units, control panels, and industrial machinery.

● Marine and Recreational Vehicles: Strip fuses are commonly used in boats, yachts, and recreational vehicles (RVs) to safeguard electrical systems and equipment. They protect circuits powering navigation lights, bilge pumps, GPS systems, marine electronics, RV appliances, and more.

● Industrial Applications: In industrial settings, strip fuses are utilized to protect electrical circuits and equipment in manufacturing plants, factories, and other industrial facilities. They are commonly found in control panels, motor controls, HVAC systems, conveyor systems, and other machinery.

● Power Distribution: Strip fuses are employed in power distribution systems to protect circuits and equipment from overcurrents. They can be used in fuse boxes, fuse panels, and distribution boards to ensure the safety and reliability of the electrical supply.

● Residential and Commercial Electrical Systems: Strip fuses are used in residential and commercial buildings to protect electrical circuits and equipment. They can be found in fuse boxes, circuit breaker panels, and electrical distribution boards, providing protection for lighting circuits, outlets, appliances, and other electrical loads.

● Renewable Energy Systems: Strip fuses are commonly used in solar power systems, wind turbines, and other renewable energy installations. They protect the electrical circuits and components of these systems from overcurrent conditions.

Stay in control, fuse your power - Order Midi Fuses Online in UK as well as best quality cable ties from UK Cable Ties today!

Things to consider while choosing the right Strip Fuse for your application:

● Current Rating: Determine the appropriate current rating required for your application. Consider the maximum current expected to flow through the circuit and choose a fuse with a rating slightly higher than that value. It's crucial to avoid using a fuse with a lower rating as it may blow prematurely or cause damage to the circuit.

● Voltage Rating: Ensure that the voltage rating of the strip fuse matches or exceeds the voltage of the circuit it will protect. Using a fuse with a lower voltage rating can lead to arcing or electrical breakdown, compromising the safety and reliability of the system.

● Fuse Type and Size: Choose the correct strip fuse type and size based on the specifications of the fuse holder or fuse panel in your application. Common types include ATO, mini, and micro fuses. Pay attention to the physical dimensions and blade configurations to ensure proper fitment.

● Application Environment: Consider the environmental conditions in which the fuse will be operating. Factors such as temperature extremes, moisture, vibrations, and exposure to chemicals or corrosive substances can affect the performance and longevity of the fuse. Select a fuse that is designed to withstand the specific environmental conditions of your application.

● Time-Current Characteristics: Understand the time-current characteristics of the fuse. This refers to how quickly the fuse will blow under overcurrent conditions. Depending on the application, you may need a fast-acting fuse for sensitive electronics or a slow-blow fuse for circuits with inrush currents.

● Standards and Certifications: Check if the strip fuse meets relevant safety standards and certifications, such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), or IEC (International Electrotechnical Commission) standards. This ensures that the fuse has undergone testing and meets specific safety requirements.

● Application Specific Requirements: Consider any specific requirements or recommendations provided by the equipment manufacturer or relevant industry standards for your application. Certain applications may have unique fuse requirements based on their specific needs or safety regulations.

Unleash the power, safeguard your circuits - Connect with UK Cable Ties to shop for the best quality Strip Fuses Online in UK!

Midi Fuses:

Midi fuses, also known as MIDI (Miniature & Intermediate Sized) fuses, are a type of strip fuse commonly used in automotive and marine applications. They are larger than standard blade fuses (ATO, mini, or micro fuses) but smaller than the larger Maxi fuses. Midi fuses are designed to handle higher current ratings and provide enhanced protection for electrical circuits in vehicles, boats, and other equipment.

Here are some key features and characteristics of Midi fuses:

● Current Rating: Midi fuses are available in higher current ratings compared to standard blade fuses. They typically range from 30 amperes up to several hundred amperes, making them suitable for applications with larger electrical loads.

● Physical Size: Midi fuses have a distinctive elongated shape. They are larger in size compared to standard blade fuses, but smaller than Maxi fuses. The extended body of the fuse accommodates larger fuse elements capable of handling higher currents.

● Mounting Style: Midi fuses often use a bolt-on or stud mount design. They have threaded studs on either end, allowing for secure and reliable installation. The bolt-on design ensures proper connection and reduces the risk of high resistance or loose connections.

● Voltage Rating: Midi fuses typically have a voltage rating of 32 volts or 58 volts, depending on the specific fuse model and manufacturer. It is important to select a fuse with the appropriate voltage rating to match the electrical system requirements.

● Application: Midi fuses are commonly used in automotive applications, such as trucks, buses, recreational vehicles (RVs), and heavy-duty equipment. They provide protection for circuits involving larger electrical loads, such as high-powered amplifiers, air conditioning systems, auxiliary lighting, power inverters, and other accessories.

● Safety and Reliability: Midi fuses are designed to provide reliable circuit protection, preventing damage to electrical systems and reducing the risk of electrical fires or hazards. They are often built with high-quality materials and undergo rigorous testing to ensure performance and adherence to safety standards.

Applications of Midi Fuses:

● Automotive: Midi fuses are widely used in automobiles, especially in heavy-duty vehicles and trucks. They protect electrical circuits that power larger components such as air conditioning systems, power windows, power seats, fuel pumps, auxiliary lighting, audio amplifiers, and other high-powered accessories.

● Marine and Recreational Vehicles: Midi fuses are commonly employed in marine vessels, boats, yachts, and recreational vehicles (RVs). They protect electrical circuits powering large marine engines, navigation systems, lighting systems, refrigeration units, entertainment systems, and other high-current devices.

● Industrial Machinery: Midi fuses are utilized in industrial machinery and equipment, where higher current requirements are common. They protect circuits powering motors, pumps, heaters, industrial control systems, conveyors, and other heavy-duty electrical components.

● Power Distribution Systems: Midi fuses are used in power distribution systems to provide circuit protection. They are often found in distribution panels, switchgear, power control centers, and other applications where higher currents need to be managed.

● Renewable Energy Systems: Midi fuses are employed in solar power systems, wind turbines, and other renewable energy installations. They protect circuits and components involved in power generation, conversion, and distribution, handling the higher currents generated by these systems.

● Heavy Equipment: Midi fuses are suitable for protecting circuits in heavy equipment such as construction machinery, agricultural machinery, mining equipment, and industrial vehicles. They safeguard electrical systems involved in powering engines, hydraulic systems, lighting, and other critical components.

● Power Inverters: Midi fuses are commonly used in power inverters, which convert DC power to AC power. They protect the inverter circuits and ensure safe operation when supplying power to appliances, tools, and other devices.

Empower your circuits, fuse with precision - Discover and buy Midi Fuses Online in UK only from UK Cable Ties!

Things to consider while choosing the right Midi Fuse for your application:

● Current Rating: Determine the maximum current that will flow through the circuit and select a Midi fuse with an appropriate current rating. Make sure the fuse's rating is higher than the expected current to provide adequate protection.

● Voltage Rating: Check the voltage rating of the Midi fuse and ensure it matches or exceeds the voltage of the circuit. Using a fuse with a lower voltage rating may result in arcing or electrical breakdown, compromising the safety and reliability of the system.

● Requirements for Application: Certain applications may have unique needs or safety regulations that dictate the type of Midi fuse to be used. Consult the manufacturer's specifications or industry guidelines to ensure compliance.

● Fuse Type and Size: Midi fuses come in various physical sizes and types. Ensure that the fuse size and type match the fuse holder or fuse block in your application. Pay attention to the mounting style, such as bolt-on or stud mount, and verify compatibility with the equipment.

● Time-Current Characteristics: Understand the time-current characteristics of the Midi fuse. Some applications may require fast-acting fuses to quickly interrupt the circuit in case of a fault, while others may require slow-blow fuses to handle temporary surges during startup or inrush currents.

● Environmental Conditions: Consider the environmental factors in which the Midi fuse will be operating. Evaluate the temperature range, moisture levels, vibrations, and exposure to chemicals or other harsh conditions. Choose a fuse that is designed to withstand the specific environment of your application.

● Safety Standards and Certifications: Check if the Midi fuse meets relevant safety standards and certifications, such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), or IEC (International Electrotechnical Commission) standards. Compliance with these standards ensures that the fuse has undergone testing and meets specific safety requirements.

● Application Support: Consult with the manufacturer or seek professional advice to ensure the proper selection of the Midi fuse for your application. They can provide guidance based on their expertise and knowledge of the specific requirements of your industry or equipment.

Fuse your way to safety - Shop for Strip Fuses Online in UK with UK Cable Ties and experience peace!

Final Thoughts:

Strip fuses and Midi fuses supplied by UK Cable Ties have distinct applications based on their current handling capabilities and physical sizes. Strip fuses, also known as blade fuses, are commonly used in automotive systems, residential and commercial electrical systems, and various industrial applications. They are well-suited for protecting circuits with lower to moderate current requirements. Strip fuses are typically found in fuse boxes, fuse panels, and distribution boards, safeguarding electrical components such as lights, radios, power windows, and appliances. Their compact size and availability in different current ratings make them versatile for a wide range of applications.

On the other hand, Midi fuses are designed to handle higher current ratings and are commonly utilized in heavy-duty automotive applications, marine vessels, industrial machinery, and power distribution systems. Their larger size and bolt-on or stud mount design make them suitable for protecting circuits powering high-current devices such as air conditioning systems, motors, pumps, and heavy machinery. Midi fu